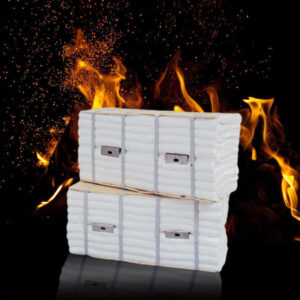

The ceramic fiber board are made of different refractory fiber bulks with excellent chemical stability, organic and inorganic bond by wet method and vacuum forming processing which is applicable to many kinds of industries .The fiber board with a characteristics of hard, flexible, excellent strength and resistance against corrosion. 1260 STD Heat Resistant Fireplace High Density Ceramic Fiber Board is produced with different alumina-silica fibers for applications at temperatures up to 1050 ℃ by vacuum formed technology. With a characteristics of hard, excellent strength, light weight and easy to handle. It is ideal material for furnace, boiler duct, stack lining and other heat equipment.

Technical Data

| Grade |

Standard |

High Pure |

High Aluminium |

Zirconium |

|||

|

Max. Temperature (°C) |

1260 |

|

1350 |

1450 |

|||

| CLASSIFICATION temperature | 1150 |

|

1260 |

1350 |

|||

| Organic Content (%) |

≤5 |

≤5 |

≤5 |

≤5 |

|||

| Thermal conductivity by mean temp. (W/m.k.) (250kg/m3) | 400°C |

0.85 |

0.85 |

||||

| 800°C |

0.132 |

0.132 |

|||||

| 100°C |

0.180 |

0.180 |

|||||

| Chemical Composition

(%) |

AL2O3 |

43 |

47 |

55 |

38 |

||

| SiO2 |

53 |

51 |

44 |

44 |

|||

| Fe2O3 + Ti2O3 |

≤1.2 |

≤0.3 |

≤0.3 |

≤0.2 |

|||

| CaO + MgO |

≤0.3 |

≤0.3 |

≤0.3 |

≤0.2 |

|||

| NaO + KO2 |

≤0.5 |

≤0.3 |

≤0.3 |

≤0.2 |

|||

| Density (kg/m3) |

280-500 |

||||||

| Size (mm) | 1000*600 1200*500 1200*1000 900*600 1000*1200

600*400 Thickness: 3-50 (Other sizes and shapes on request. ) |

||||||

| Package |

Carton box |

||||||

| Certificates |

ISO9001-2008; MSDS |

||||||

Features

♦ High compression strength

♦ Non–fragile materials and good toughness

♦ Accurate dimension and good paleness

♦ Even fiber with stable property

♦ Excellent heat stability&thermal shock resistance

♦ Easy to install

Application

♦ Ceramic industry-lining of various kilns for thermal insulation

♦ Petrochemical and metallurgy industries- back linings, wall linings, and ling thermal insulation

♦ Glass kiln lining and back lining thermal insulation

♦ Heat treatment furnace kiln back lining thermal insulation

♦ Aluminum factories-reduction cell firebricks back linings

♦ High temperature reaction, heating device-wall lining and back linings