Product Category

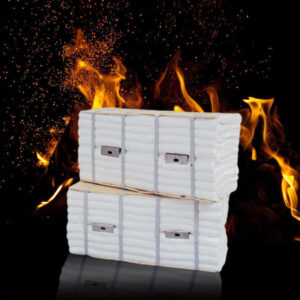

- COM ceramic fiber bulk -1050

- ST ceramic fiber bulk -1260

- HP ceramic fiber bulk -1260

- HA ceramic fiber bulk -1360

- HZ ceramic fiber bulk -1430

Technical Specifications

| Item Product | COM | ST | HP | HA | HZ |

| Classification Tem(℃) | 1050 | 1260 | 1260 | 1360 | 1430 |

| Working Tem(℃) | 950 | 1050 | 1100 | 1200 | 1350 |

| Color | White | White | White | White | White |

| Fiber dia blowing(um) | 2–3 | 2–3 | 2–3 | 2–3 | 2–3 |

| Fiber dia Swing(um) | 3—4.5 | 3—4.5 | 3—4.5 | 3–4 | 3–4 |

| AL2O3(%) | 42–44 | 45–46 | 47–49 | 52–55 | 39–40 |

| AL2O3+SIO2(%) | 96 | 97 | 99 | 99 | ——- |

| AL2O3+SIO2+ZrO2(%) | ——– | ——- | ——- | ——– | 99 |

| ZrO2(%) | ——– | ——- | ——- | ——– | 15–17 |

| Fe2O3(%) | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

| Na2O+K2O(%) | <0.5 | <0.5 | 0.2 | 0.2 | 0.2 |

Product Description

Ceramic fiber cotton, the general ceramic fiber cotton through the fused coke gemstones, injection / rejection silk pro duction process from fibrillation. High-purity, high alumina ceramic fiber cotton through the fused alumina and silic a mixture, injection / rejection silk production process from fibrillation. Zirconium ceramic fiber cotton through the fused alumina, silica and zirconia mixture, injection / rejection from the production of silk fiber. The use of injection into the production process of ceramic fiber cotton fiber for raw materials, manufactured by vacuum forming process Ceramic fiber textiles are cotton standard ceramic fiber rejection suspect a special treatment process, from deal with processing, the fiber diameter uniformity, spinning rate, and are ideal for t he production of textile raw materials.

Product Characteristics

- Low heat capacity, low heat conductivity.

- Excellent chemical stability.

- Excellent thermal stability, high temperature is not easy pulverization.

- Non-binding agents and corrosive substances.

- Excellent sound-absorbing nature.

Product Applications

- Fiber blanket and board products of raw materials.

- Fiber textile materials.

- High-temperature furnace, heating devices, the wall lining the gap filler.

- Wet raw material products.

- Fiber spraying, castable ,smear raw materials.

- Corner and complexity of space-filling insulation material.